Dry Ice Blasting: Efficient and Eco-Friendly Industrial Cleaning

Discover the power of dry ice blasting for eco-friendly industrial cleaning. Learn how it works, benefits, applications, and FAQs.

Dry Ice Blasting is an effective and environmentally friendly solution in the realm of industrial cleaning. This guide explores the process, advantages, applications, and addresses common questions about this innovative method.

The Science Behind Dry Ice Blasting

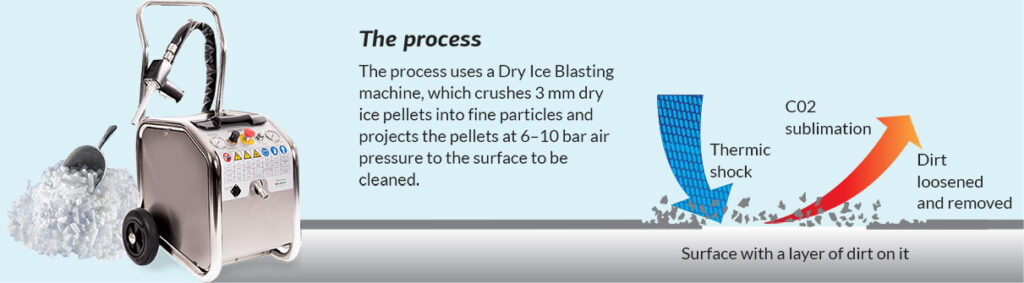

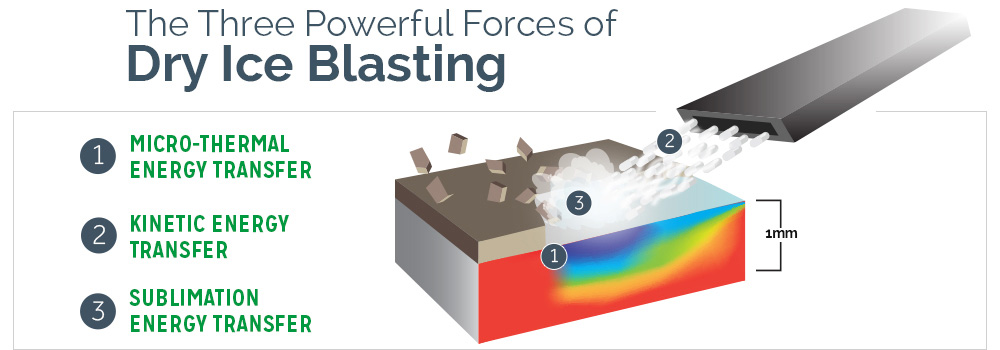

Dry ice blasting, also known as CO2 blasting, is a cleaning method that utilizes solid carbon dioxide (CO2) pellets. These pellets sublimate upon impact, transitioning directly from a solid to a gas, effectively lifting away contaminants without leaving behind any residue. This method is both efficient and environmentally conscious.

How Dry Ice Blasting Works:

Solid CO2 pellets are accelerated using compressed air, creating a force that breaks the bond between contaminants and surfaces. The combination of the cold temperature and kinetic energy removes grime, resulting in a clean surface without the production of secondary waste.

Key Advantages:

| Advantage | Description |

|---|---|

| Environmentally Friendly | Dry ice blasting is non-toxic, chemical-free, and produces no waste, making it an environmentally responsible choice. |

| Gentle and Effective | This method is non-abrasive, making it safe for delicate surfaces, machinery, and electronics. |

| Versatile Applications | From machinery to food processing lines, it effectively removes grease, paint, adhesives, and more. |

| Minimal Downtime | Unlike traditional methods, it can be done in place, reducing downtime and operational disruptions. |

| Cost-Effective | While the initial investment may be higher, it leads to reduced labor, shorter cleaning times, and less waste. |

Applications of Dry Ice Blasting

| Application | Description |

|---|---|

| Industrial Equipment Cleaning | Efficiently removes contaminants from heavy machinery and manufacturing equipment without causing damage. |

| Graffiti and Coating Removal | Safely strips graffiti, paint, and coatings from surfaces like concrete, brick, and metal. |

| Fire Damage Restoration | Cleans soot and smoke residue after a fire, restoring surfaces to their pre-damaged state. |

| Electrical Equipment | Ideal for cleaning electrical components, ensuring optimal performance and reducing the risk of malfunctions. |

Video: Dry Ice Blasting Gas Turbines

FAQs About Dry Ice Blasting

| Question | Answer |

|---|---|

| Is it environmentally safe? | Absolutely. Dry ice blasting uses CO2 pellets that leave no chemical residue, making it environmentally safe. |

| Can it damage surfaces? | No, dry ice blasting is non-abrasive and safe for delicate surfaces. |

| How does it compare to sandblasting? | Unlike sandblasting, dry ice blasting is non-abrasive, safer, and doesn’t produce secondary waste. |

| Is it effective against oil and grease? | Yes, dry ice blasting effectively removes oil, grease, and other contaminants from surfaces. |

| Which industries use it? | Dry ice blasting finds applications in various industries, including manufacturing, automotive, and food processing. |

| Can I do it myself? | Dry ice blasting requires specialized equipment and training, so it’s recommended to hire professionals for optimal results. |

Conclusion

Dry Ice Blasting presents an efficient, eco-friendly, and versatile approach to industrial cleaning. Its ability to remove contaminants without causing harm to delicate surfaces positions it as a transformative solution in the field of cleanliness. Let Pro-Blast Services Inc. be the company to clean your company from top to bottom.